Description

![]()

Ultio slides are sold as singles, so order two units if a pair is required

REDUCED 20% FOR CLEARANCE!

The 8027 telescopic slide is now now discontinued on production, with only reducing stock remaining. For new projects we recommend replacement slide 6526 from our own manufactured Radial Range.

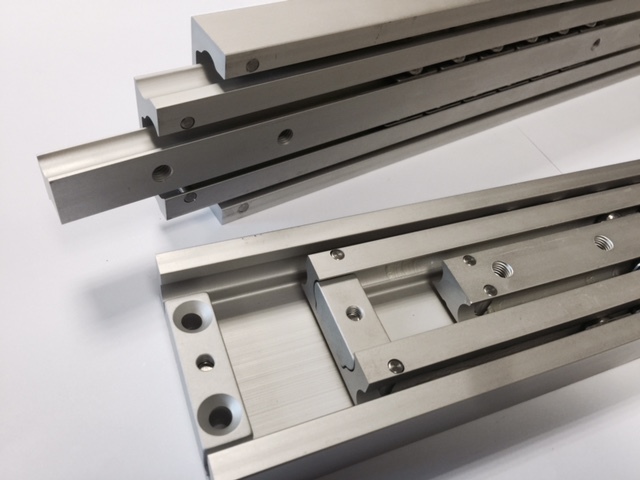

The 8027 slide is part of the new ULTIO range of slides. Manufactured with state of the art production methods, ULTIO slides benefit from high quality materials including professionally extruded high strength sections.

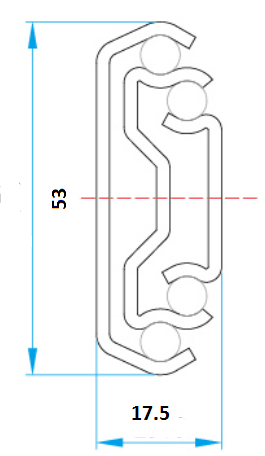

The 8027 slide is corrosion resistant. The ball cages, bearings and components are manufactured from grade 304 stainless steel. The aluminium sections are aircraft grade 7005 with a T53 temper strength, comparable to steel. Alloy 7005 is heavily utilized by the aircraft and ordnance industries due to its superior strength. The movement is incredibly smooth and almost silent. There is absolutely no play between the unloaded beams and they are factory fitted with a slight pre-load.

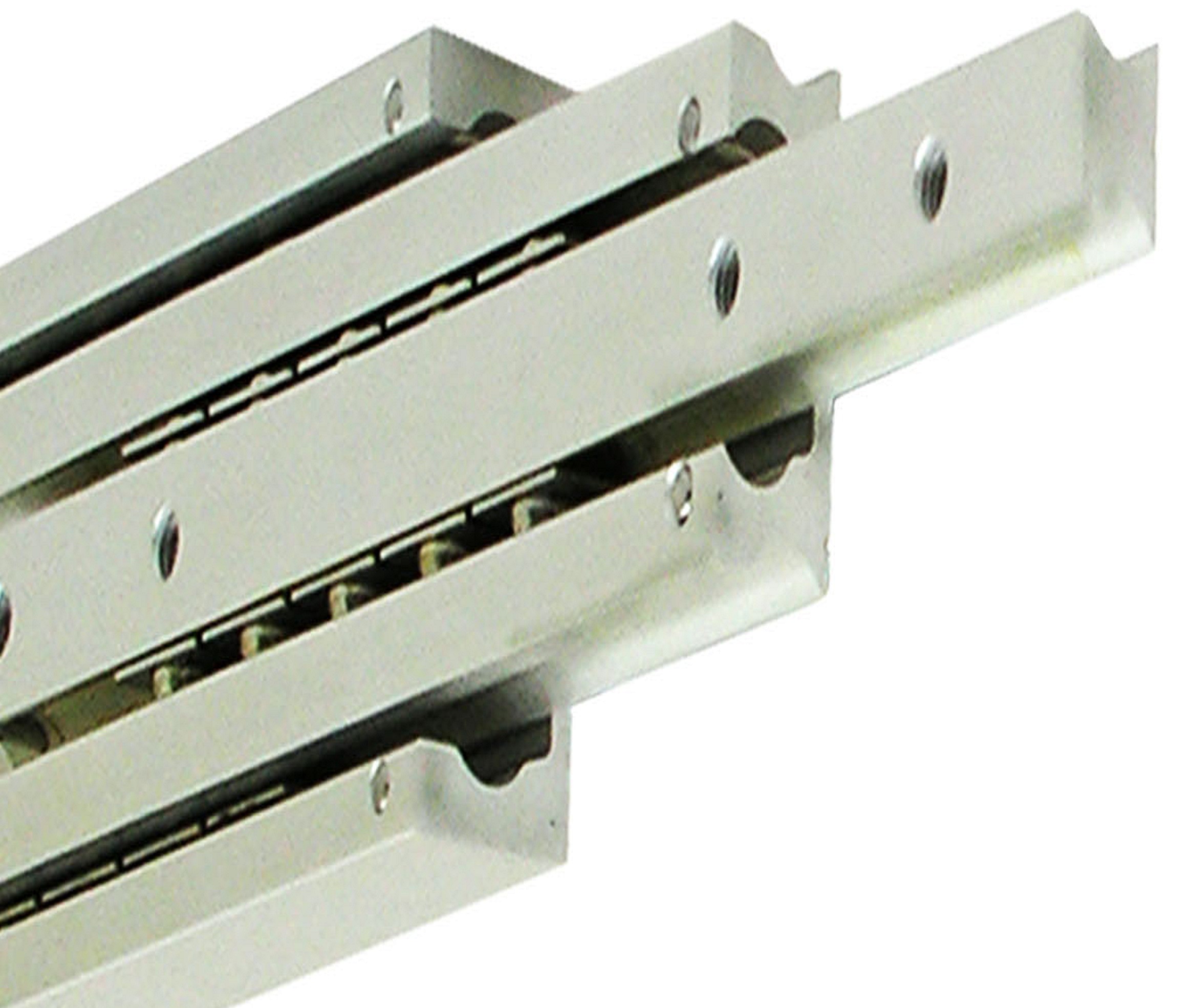

There are no corrosive parts used in the manufacture and it is suitable for wash down conditions. Load rating at 600mm is 330kg per extended pair. All ULTIO slides are interchangeable with other European manufacturers whilst offering higher quality at more competitive price points. The slide has been designed specifically to replace heavy steel slides in the manufacture of fire trucks. The weight saving and non corrosive properties are demanded by builders and brigades. Unlike other slide manufacturers, our 8027 slide benefits from extremely high grade sections, so stainless steel bearings can operate within the ball tracks and provide the same strength as the steel predecessors. We do not use plastic ball bearings in the manufacture of our slides.

Applications for the 8027 slides are military and rescue vehicle drawers, aircraft seating, shipborne racking and ATMs. Ultio 8027 slide weighs 4kg per metre. Slide travel is 100% of the closed length = stated extension +15mm.

The 8027 slide is tested at 20,000 operational cycles, with the slides spaced 1000mm apart. At 550mm length, with full extension and SWL loading of 320kg, the slides deflect 10mm. Tested to 400kg loading on 1,000 cycles, the deflection increases to 16mm. Deflection is the measurement of drop taken at the full extension of the slides and influences the ease of operational forces to close and open the drawer. At 320kg loading the operational forces are less than 10kg. At 400kg loading this increases to 16-20kg. During both tests, the drawer was stable without any side load movement or damage to the raceways, due to the high grade of alloy used in the construction of the beams.

Prices are per single slide. Loadings are given per extended pair. There are two slides per pair. The Ultio 8027 is available from stock across all key lengths.

Download DatasheetSPECIFICATION

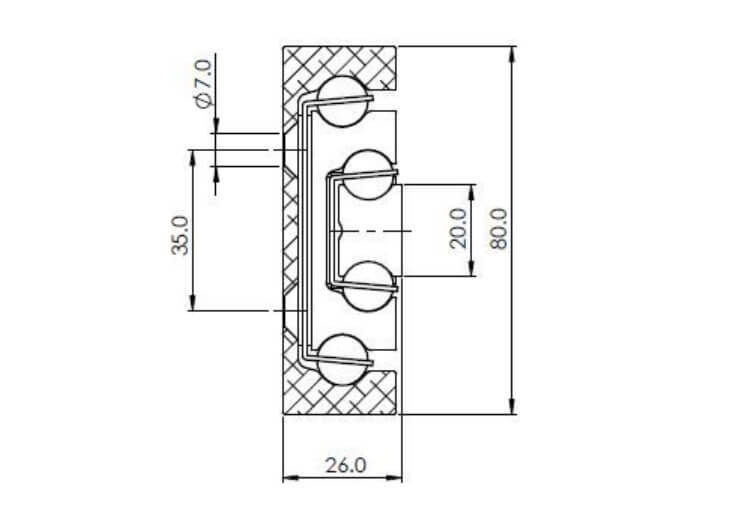

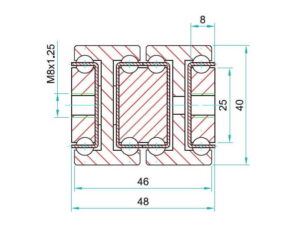

Space Envelope Width: 26mm

Height: 80mm

Closed Length: 300-1000mm

Extension Length: 285-985mm

Maximum Load Capacity: 240-330 kg/pair

Extension Type: Total

Material: Aluminium 7005 – Aircraft Grade

Tom Byron –

Have you guys any knowledge of the Accuride AL4160 slider? It looks totally identical but at $267 for the 22” length in the US, seems a load more expensive. Your slide is $146 and a higher grade aluminum I think?

Reply from admin:

Hi Tom. Yes the slides are totally interchangeable and I’m pleased you’re happy with our products. We can’t comment on competitor pricing. We can confirm that our slide is Aircraft grade aluminum and the bearings are stainless steel.

James –

Received the two pairs a day after ordering. They are very high quality. The load capacity is easily attained.

Liam fraser –

I ordered the 550mm slides on Monday and recieved on the Tuesday morning. They have a high quality feel and are smooth in operation. They support the loading with ease.

Jeremy –

nice bit of kit!

Ian –

The slides took 4 weeks to arrive as advised. I now believe they are a stock item. The steel slides they replaced were heavy and highly corroded. Extra small bearings had detached between the beams and the slide had jammed. The new aluminium slides fitted into their exact place as confirmed by a Sliding Systems rep.

Already I can see this is a quality product and it will have a long service life.

Anonymous –

we received the slides today. They were well packed and within the two weeks quoted. At 24″ they have a super smooth opening. The aluminum doesn’t mark or wear. The technical support was there without delay and dealing direct with these guys wasn’t a problem.

Frank Molner –

This hi-grade aluminum slide has just arrived on my desk. If it works as well as it feels then we’ll be ordering a lot more. Thanks to Jon for his technical support, night and day, it’s appreciated.

The product review: The material is hi-grade aircraft aluminum, which at T6 provides steel strength. The components are all 304 stainless, so there is no fear of corroding. Metric screw threads on the inner beams, but ask nicely and these guys will source them. Outer holes can take imperial c’sk. The travel is ultra smooth and the only noise is from the alloy to alloy stops.

We are fitting them to truck draws at 26″ or 650mm