Radial Aero Slide 5220 (170kg) Grade 7075 Alloy. Non-Corrosive, Hi-Load & Raceway Wipers

£109.75 – £269.76

CompareDescription

Radial telescopic slides are sold as singles, so order two units if a pair is required

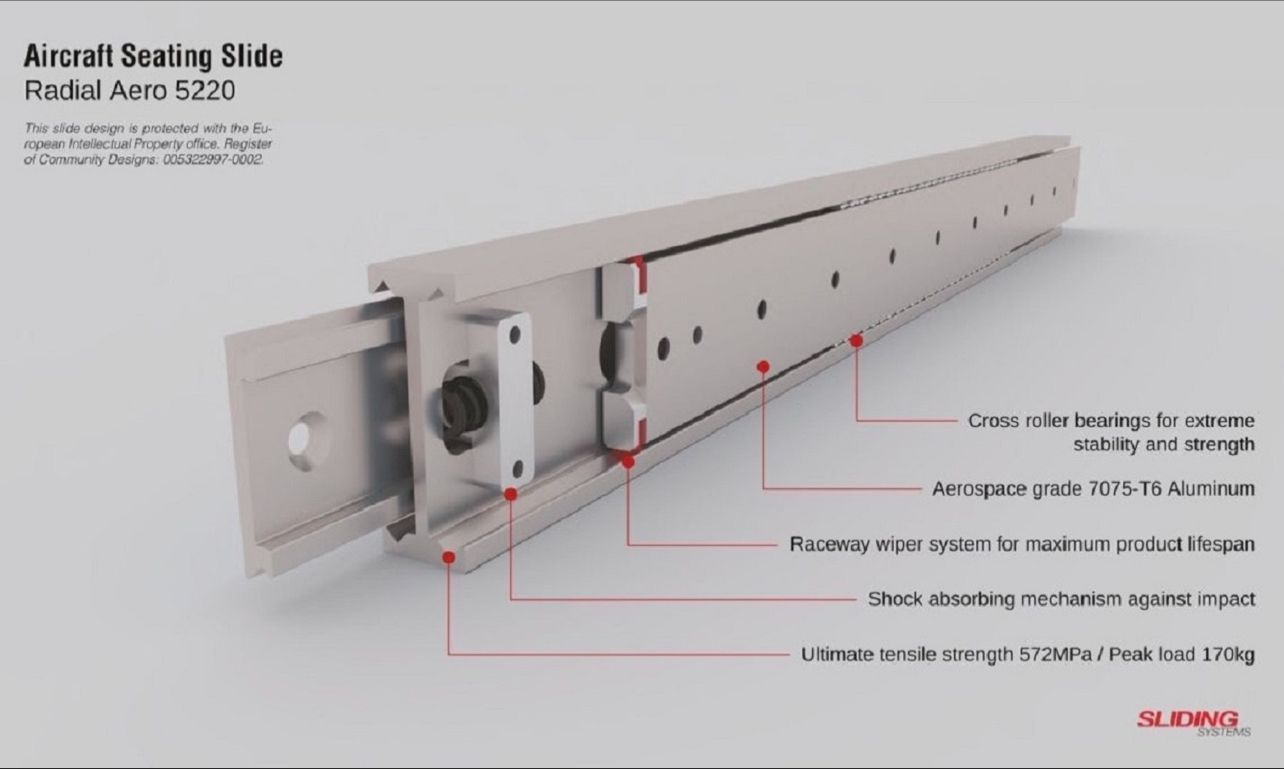

This new benchmark in high strength alloy slides is manufactured by Sliding Systems to reinforce our position as a global leader in the design, manufacture and world wide distribution into the emergency and military vehicle market.

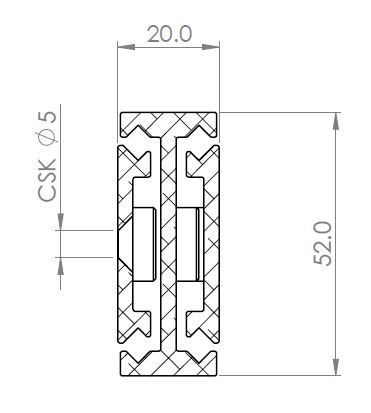

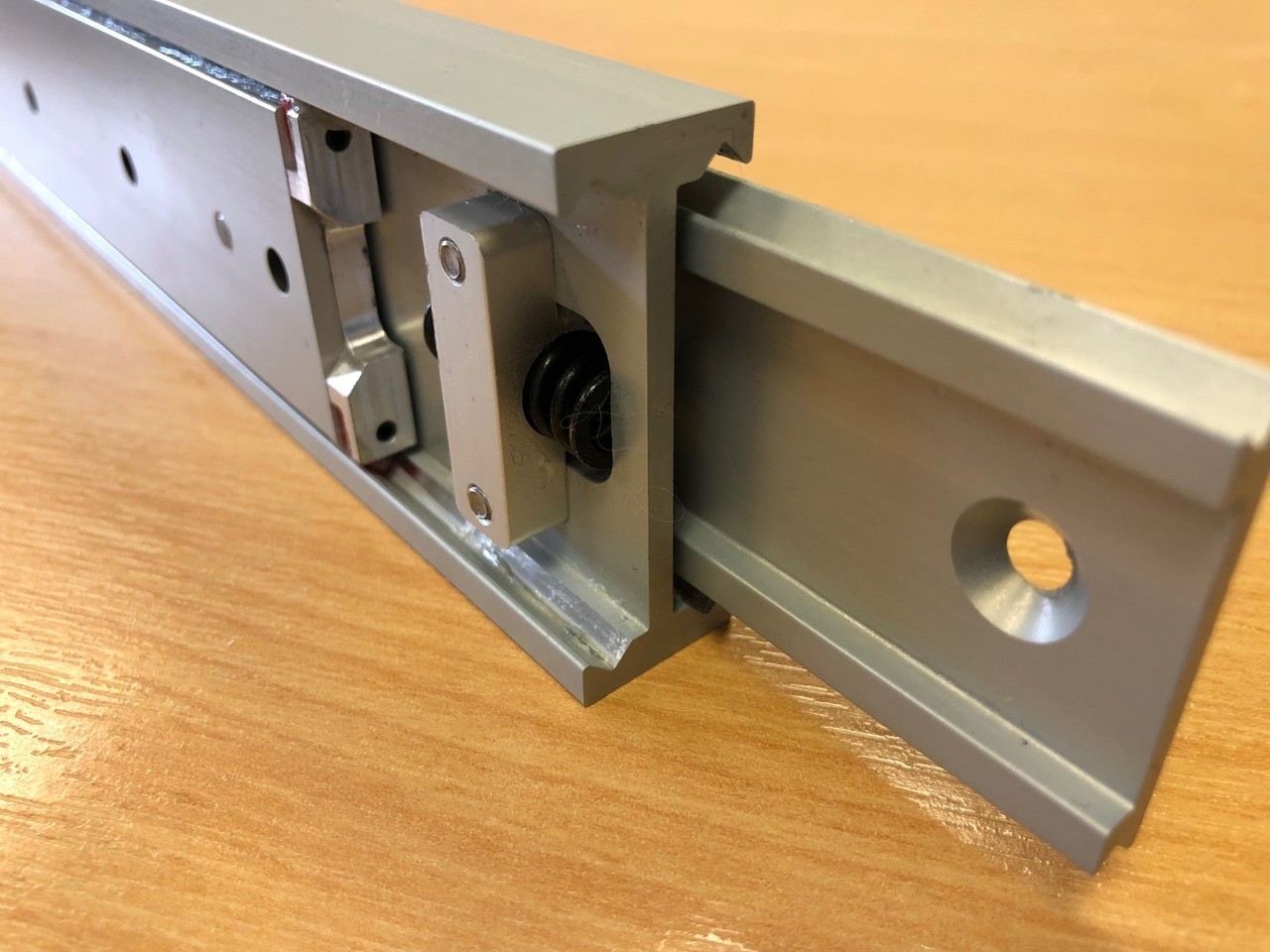

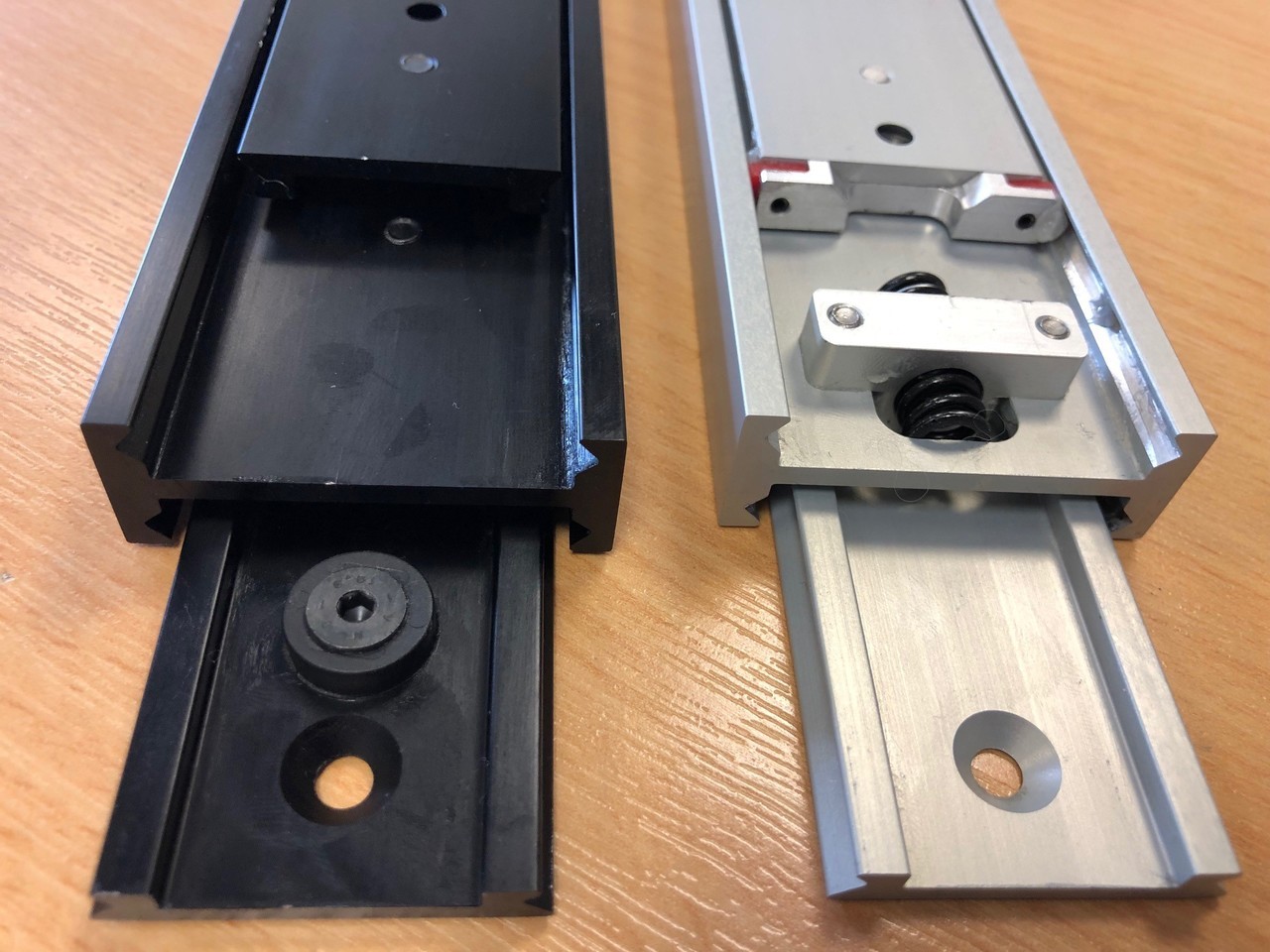

The 5220 Radial Aero Slide is developed for vehicle mounted drawer systems requiring strong, lightweight and non-corrosive properties. The beams are manufactured from high strength 7075 T6 aerospace alloy, which has similar load carrying properties to cold drawn steel. Stainless steel 316L caged cross rollers are used to provide stability, strength and very low deflection when fully extended. The compact design incorporates a height of only 52mm with 20mm slim width. We can manufacture the slides as standard, from 300mm up to 1,000mm, complimenting the heavier duty 6526 Aero slide. By using high grade materials we can produce a lightweight, compact slide which weighs only 1.19kg at 600mm. This is 30% of the weight of equivalent steel slides used in fire trucks.

Load capacities are equivalent to plated steel variants with a peak loading of 170kg per extended pair and high safety margin. We do not use load bearing plastic components within this product. This slide is designed to operate in hostile military conditions, reduce vehicle weight (meeting emissions targets) and eliminate corrosion from wet lockers, extending product life substantially. By manufacturing the beams from aerospace 7075 T6 alloy we are able to more than match the strength of equivalent steel slides.

Uniquely, this slide has an internal wiper system to protect against dirt ingress and heavy duty die springs to absorb impact when slammed. The slide is designed with minimal access areas for contamination to enter the bearing tracks, making it ideal for military usage in rough terrains. We have used our expertise in defence engineering to produce a high performance slide budgeted for emergency truck builders. Other markets include military, marine, solar panels, machine building and long length roof-lights.

Material characteristics of 7075-T6 aluminium provide a very high strength material used for highly stressed structural parts, recommended and used widely in aircraft fittings. Rockwell A hardness is 53.5 HRC. Ultimate tensile strength is 572 MPa. The 5220 Aero slide at 450mm length with a 480mm travel has been independently (cyclically and abuse) tested to 60,000 cycles with a 100kg load, passing all criteria for aircraft seating use. Delrin rollers and aerospace specific back stops can be fitted to reduce weight further. The 5220 Aero slide can be produced with black hard anodisation in aerospace format. In standard format, the slides are supplied in anodised silver matching the 6526 Aero.

For the aerospace version of the 5220, we modify the fixing hole countersinks from 90 degs to 100 degs. This conforms to aerospace standard fastenings. Please advise if required.

Aero slide design is protected with the European Intellectual Property Office, Register of Community Designs:005322997-0002. Ask our engineers for further information. The 5220 slides require 4-5 weeks production, or are stocked for call-off against OEM schedules.

Download Datasheet

SPECIFICATION

Space Envelope Width: 20mm

Height: 52mm

Closed Length: 300-1000mm

Extension Length: 300-1000mm

Maximum Load Capacity: 125-170 kg/pair

Extension Type: Total

Material: Aluminium 7075 T6

3D CAD VIEW

1 review for Radial Aero Slide 5220 (170kg) Grade 7075 Alloy. Non-Corrosive, Hi-Load & Raceway Wipers

Related products

-

Select options This product has multiple variants. The options may be chosen on the product page Compare

Select options This product has multiple variants. The options may be chosen on the product page CompareFront Handle: Die-Cast Heavy Duty Aluminium Black or Yellow

£17.49 – £19.83Quick View -

Select options This product has multiple variants. The options may be chosen on the product page Compare

Select options This product has multiple variants. The options may be chosen on the product page CompareQuick Fist 3″ Nozzle Clamp – Holds from 70 to 83mm (2 3/4″-3 1/4″) dia.

£16.86 – £2,361.06Quick View

James –

All queries were answered within a couple of minutes and to a very high standard. I had 3D drawings mailed over at 11pm, which was much appreciated. The order process was simple and I received the slides within 48 hours. The quality matches their service, so no worries there.