QSRT-120 (200-680 kg/pr) Super Extension 150%

£319.79 – £1,982.25

CompareDescription

Professional Range slides are sold as singles, so order two units if a pair is required

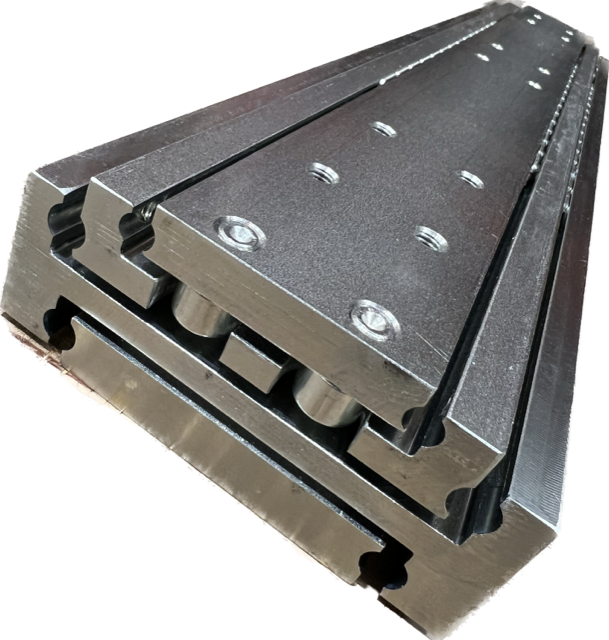

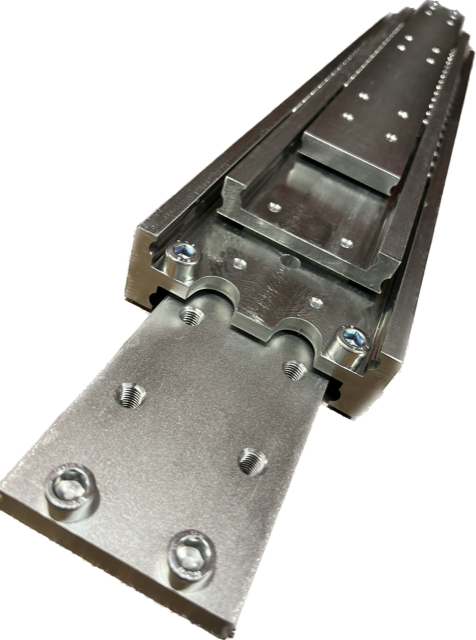

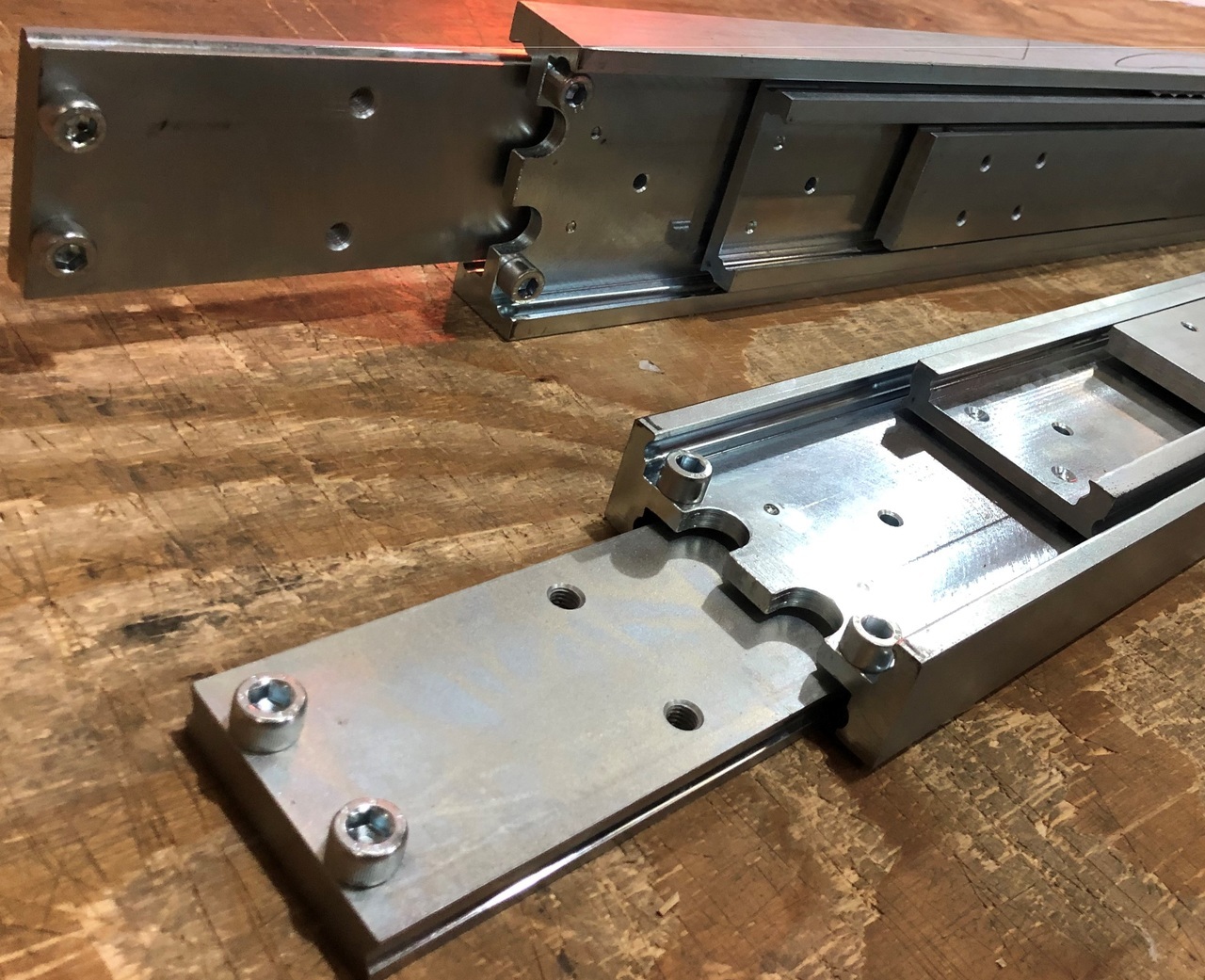

Four beam telescopic slides enable the drawer to be extended out 150% from the stowed position. A closed length of 1,000mm can provide 1,500mm of travel (2,500mm fully extended). Ideal for vehicle use where fitting space is limited. The QSRT-120 is designed to extract under-slung train battery boxes which are fixed to the mid-point of the chassis. This provides necessary extra travel required to completely clear the train for servicing.

The QSRT-120 is an extreme load/duty super extension telescopic slide (200-680 kg/pair) suitable for a wide range of applications. At 550mm 1 pair has a full extension load capacity of 640 kg.

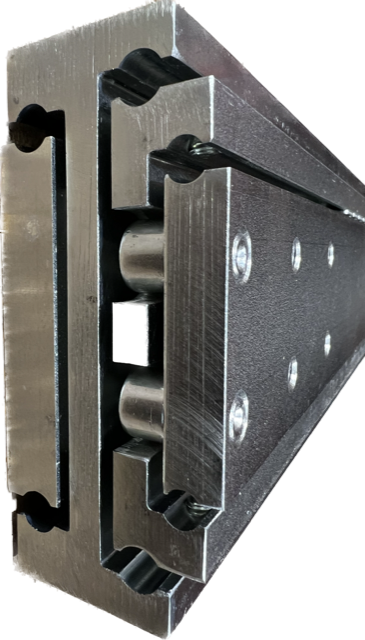

Constructed from cold drawn steel sections and fitted with caged ball bearings, the QSRT-120 telescopic slide has an excellent level of resistance to shock and vibration when supporting a dynamic load in the closed position. Accordingly, this slide is well suited to mounting on vehicles. This is a very strong compact slide, utilising the I beam format, which offers high resistance against axial and coaxial torque loading. Resulting in minimal deflection at full extension and low operating forces.

Additional product variations can be produced with bespoke closed lengths, extensions, mounting options, surface treatments and stainless ball bearings/cages. We do not recommend QSRT slides are fitted in the minor axis (flat), without due consideration to substantial load reductions.

The production process is ISO9001-2015 accredited. Our steel telescopic slides are manufactured from cold drawn steel C45E+C in accordance with EN 10277. Laser cut ball cages are manufactured from zinc plated sheet metal, and the ball bearings are carbon steel C85 G100 in accordance with DIN 5401. Standard Professional Range steel slides are RoHS & REACH certified to withstand over 1,000 hours corrosion protection, until the appearance of red rust. This is due to the investment made in our own state of the art electrolytic alkaline zinc processing facility. Core steel C45 E+C, with a layer depth of 10-12 microns conforming to DIN EN ISO 9227 neutral salt spray testing. No white rust appearance within 120 hours. No red rust within 1,032 hours.

An individual slide weighs 36.67 kg per metre.

Prices are per single slide. Loadings are given per extended pair. There are two slides per pair. The QSRT-120 is manufactured to order; please allow 5-6 weeks for delivery or can be stocked for immediate call off against scheduled orders.

Download DatasheetSPECIFICATION

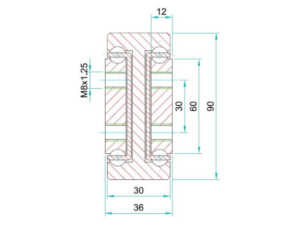

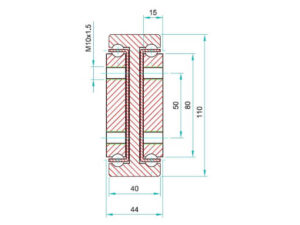

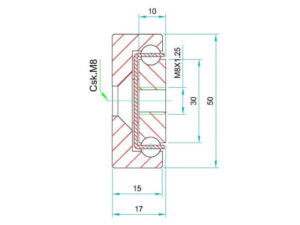

Space Envelope Width: 52mm

Height: 120mm

Closed Length: 300-2000mm

Extension Length: 450-3000mm

Maximum Load Capacity: 200-680 kg/pair

Extension Type: Over – 150%

Material: Steel

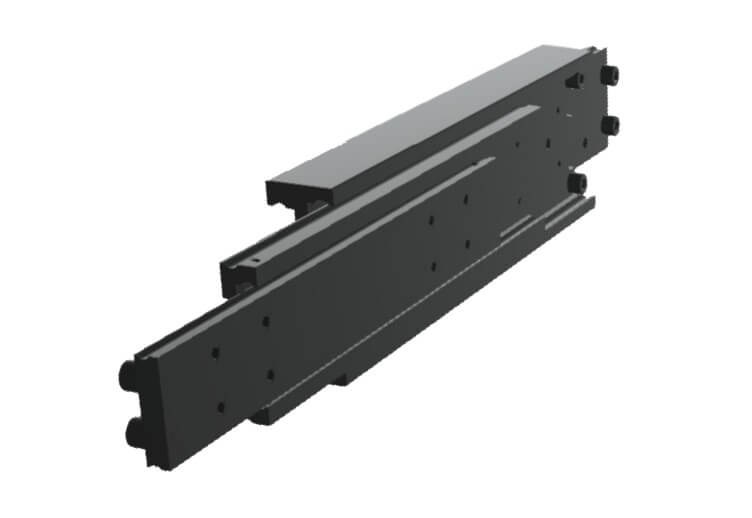

3D CAD VIEW

Related products

-

Select options This product has multiple variants. The options may be chosen on the product page Compare

Select options This product has multiple variants. The options may be chosen on the product page CompareDTS-90 Full Ext’n (220-1050kg/pr)Mobile ‘I’ Beam

£108.60 – £1,366.97Quick View -

Select options This product has multiple variants. The options may be chosen on the product page Compare

Select options This product has multiple variants. The options may be chosen on the product page CompareDTS-110 Full Ext’n (160-1800kg/pr)Mobile ‘I’ Beam

£211.02 – £1,864.58Quick View -

Select options This product has multiple variants. The options may be chosen on the product page Compare

Select options This product has multiple variants. The options may be chosen on the product page CompareOWS-50 Partial Extension (70-485 kg/pair)

£41.66 – £334.69Quick View

Reviews

There are no reviews yet.