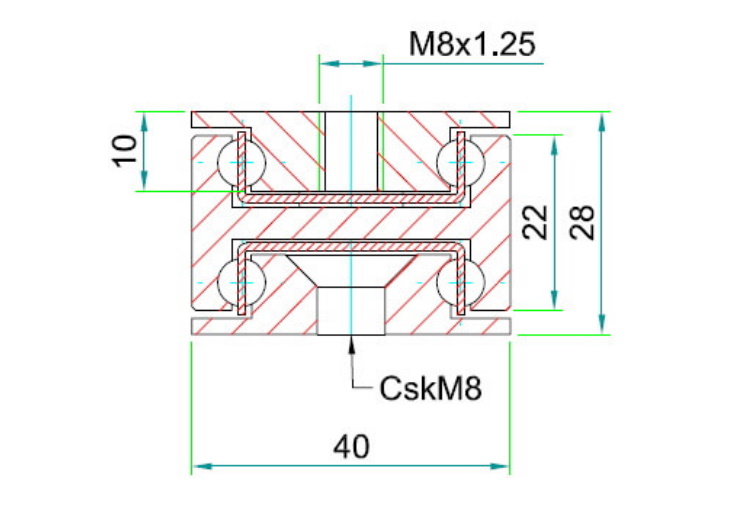

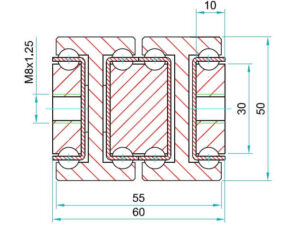

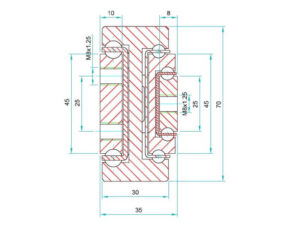

KDTS-40 Base/Flat Mounted Full Extension (15-100 kg/pair)

£62.18 – £433.77

CompareDescription

Professional Range slides are sold as singles, so order two units if a pair is required

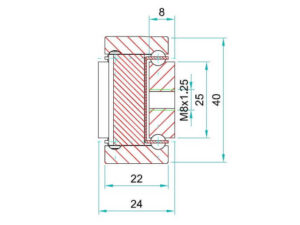

The KDTS-40 is designed to be mounted flat, particularly on a truck floor, as a base mount. Maximising strength from a small space envelope. The base beam has countersunk holes to secure into the floor, whilst the upper beam is threaded to drop a generator, pump carrier or large drawer upon. The outer flanges milled around the beams not only increase load capacity but reduce potential for dirt ingress when operating on the indirect axis.

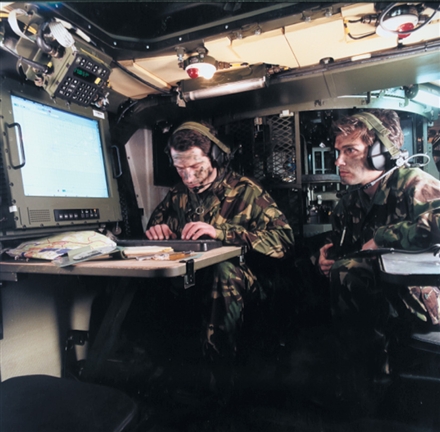

The KDTS slides are also suited to industrial seating and military/emergency vehicle stowage, it has a wide range of applications where torsional strength is paramount. As this slide is also available in 316L stainless steel material, it can be adapted to the marine environment.

This is an extreme load/duty, full extension telescopic slide (15-100 kg/pair). At 550mm 1 pair has a full extension load capacity of 100 kg. Constructed from cold drawn steel sections and fitted with caged ball bearings, the KDTS-40 telescopic slide has an excellent level of resistance to shock and vibration when supporting a dynamic load in the closed position. Accordingly, this slide is well suited to mounting on vehicles. This is a very strong compact slide, utilising the I beam format, which offers high resistance against axial and coaxial torque loading. Resulting in minimal deflection at full extension and low operating forces.

Additional product variations can be produced with bespoke closed lengths, extensions, mounting options, surface treatments and stainless ball bearings/cages. The KDTS-40 drawer slide may also be fitted in the major axis (upright). The load capacity will increase toequal standard DTS mounting configuration. It can be supplied with a 120% extension, which will increase the deflection at full extension. Please consult our sales engineers for this no cost option.

The production process is ISO9001-2015 accredited. Our steel telescopic slides are manufactured from cold drawn steel C45E+C in accordance with EN 10277. Laser cut ball cages are manufactured from zinc plated sheet metal, and the ball bearings are carbon steel C85 G100 in accordance with DIN 5401. Standard Professional Range steel slides are RoHS & REACH certified to withstand over 1,000 hours corrosion protection, until the appearance of red rust. This is due to the investment made in our own state of the art electrolytic alkaline zinc processing facility. Core steel C45 E+C, with a layer depth of 10-12 microns conforming to DIN EN ISO 9227 neutral salt spray testing. No white rust appearance within 120 hours. No red rust within 1,032 hours.

An individual slide weighs 6.75 kg per metre.

Prices are per single slide. Loading is given per extended pair. There are two slides per pair. The KDTS slides are manufactured to order. Please allow 5-6 weeks. For OEM volumes and stock support, please consult our sales engineers.

Download DatasheetSPECIFICATION

Space Envelope Width: 40mm

Height: 28mm

Closed Length: 200-1600mm

Extension Length: 200-1600mm

Maximum Load Capacity: 15-100 kg/pair

Extension Type: Total

Material: Steel

3D CAD VIEW

Related products

-

Select options This product has multiple variants. The options may be chosen on the product page Compare

Select options This product has multiple variants. The options may be chosen on the product page CompareDDTS-50 (100-240 kg) Super Extension 200%

£103.67 – £718.45Quick View -

Select options This product has multiple variants. The options may be chosen on the product page Compare

Select options This product has multiple variants. The options may be chosen on the product page CompareQSRT-70 (100-310 kg/pr) Super Extension 150%

£146.51 – £666.95Quick View -

Select options This product has multiple variants. The options may be chosen on the product page Compare

Select options This product has multiple variants. The options may be chosen on the product page CompareDTSB-40 (40-350kg/pr) Full Ext’n Bi-Directional

£54.78 – £433.17Quick View

Reviews

There are no reviews yet.