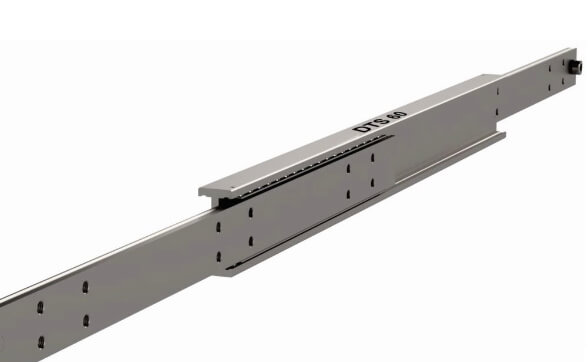

DTS-60 Full Ext’n (180-600kg/pr) Mobile ‘I’ Beam

£73.76 – £477.90

Description

Professional Range slides are sold as singles, so order two units if a pair is required

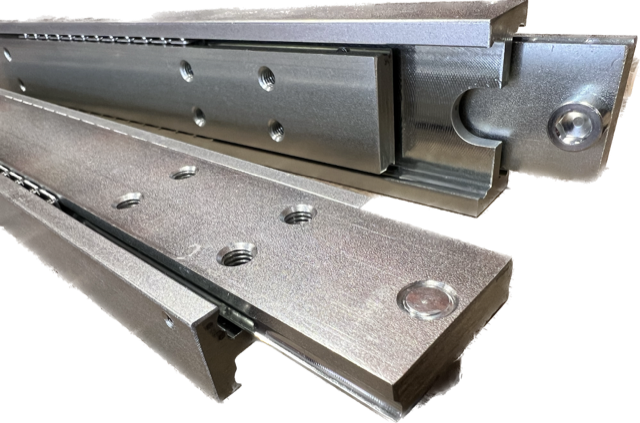

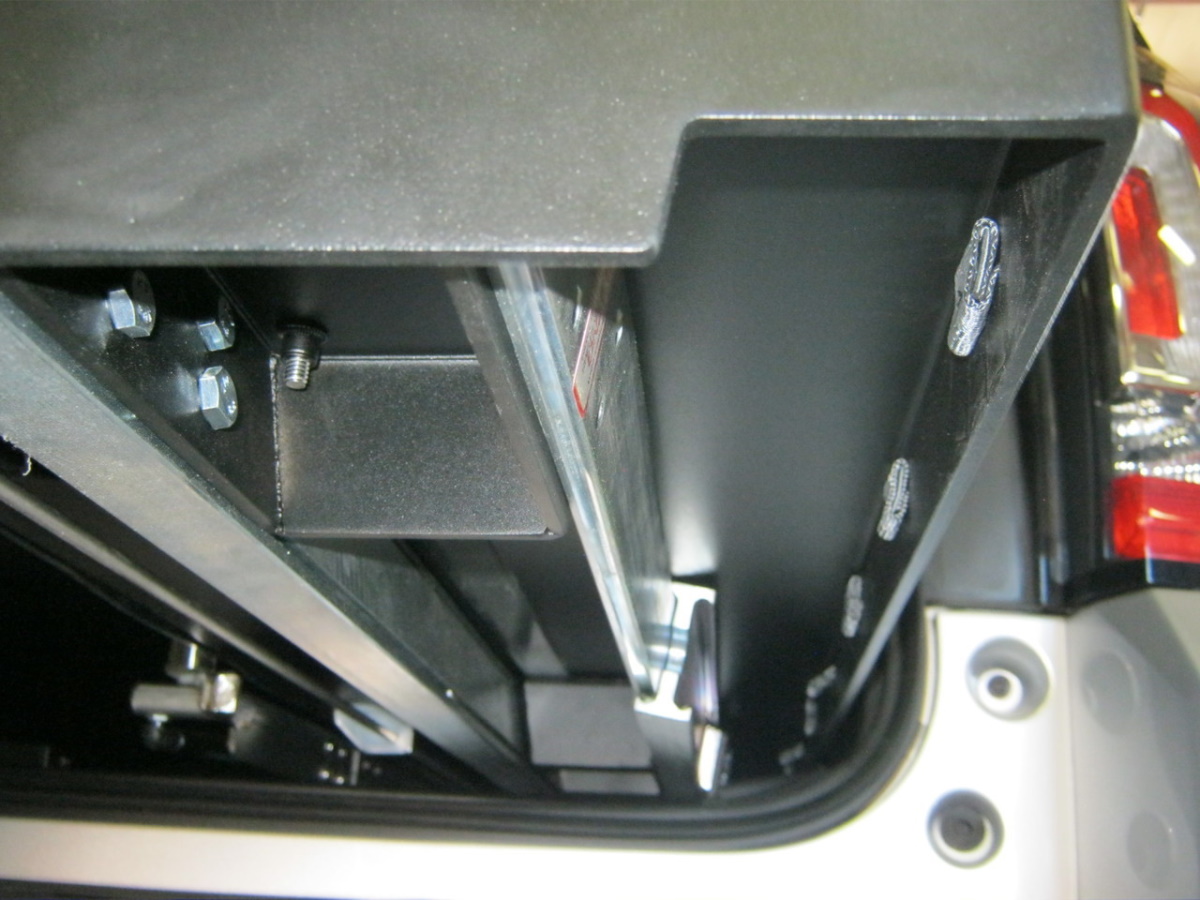

The DTS-60 is a rugged, strong and very compact telescopic slide, which has been designed for load maximisation from a small space envelope. Particularly suited to train battery boxes, military generators and access platforms, it has a wide range of applications where torsional strength is paramount. As this slide is also available in 316L stainless steel, it is specified throughout the defence industry for land and sea systems, where product interchangeability by operational environment is paramount.

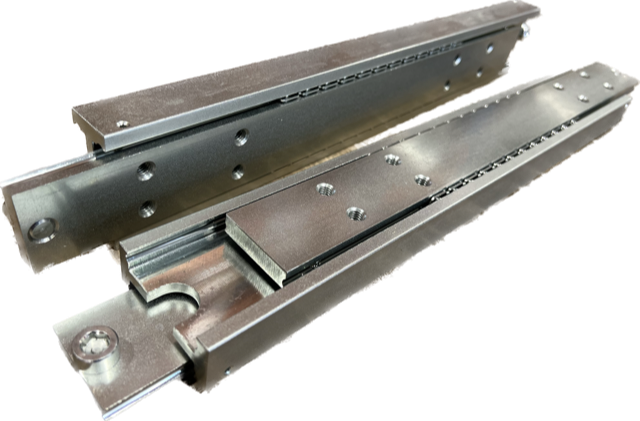

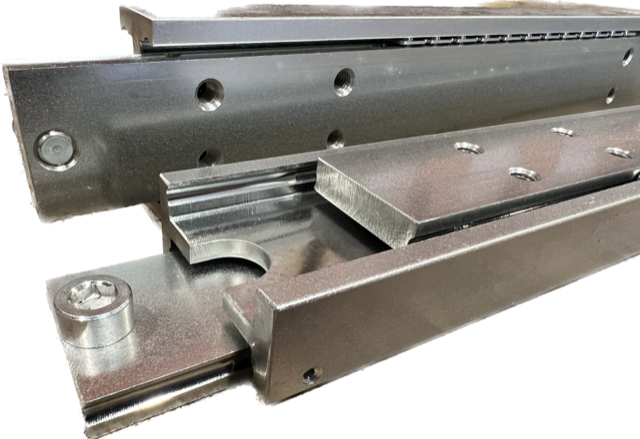

The DTS-60 is an extreme load/duty, full extension telescopic slide (180-600 kg/pair). At 550mm 1 pair has a full extension load capacity of 550 kg. Constructed from cold drawn steel sections and fitted with caged ball bearings, the DTS-60 telescopic slide has an excellent level of resistance to shock and vibration when supporting a dynamic load in the closed position. Accordingly, this slide is well suited to mounting on vehicles. This is a very strong compact slide, utilising the I beam format, which offers high resistance against axial and coaxial torque loading. Resulting in minimal deflection at full extension and low operating forces.

Additional product variations can be produced with bespoke closed lengths, extensions, mounting options, surface treatments and stainless ball bearings/cages. The DTS-60 drawer slide may also be fitted in the minor axis (flat). However, the load capacity will be reduced by 60-80% of the stated loading. It can be supplied with a 120% extension which will reduce the load slightly. Please consult our sales engineers for this no cost option.

The production process is ISO9001-2015 accredited. Our steel telescopic slides are manufactured from cold drawn steel C45E+C in accordance with EN 10277. Laser cut ball cages are manufactured from zinc plated sheet metal, and the ball bearings are carbon steel C85 G100 in accordance with DIN 5401. Standard Professional Range steel slides are RoHS & REACH certified to withstand over 1,000 hours corrosion protection, until the appearance of red rust. This is due to the investment made in our own state of the art electrolytic alkaline zinc processing facility. Core steel C45 E+C, with a layer depth of 10-12 microns conforming to DIN EN ISO 9227 neutral salt spray testing. No white rust appearance within 120 hours. No red rust within 1,032 hours.

An individual slide weighs 10.61 kg per metre.

Prices are per single slide. Loadings are given per extended pair. There are two slides per pair. The DTS-60 is stocked across all key lengths. For higher volume or non-standard lengths, please allow 5-6 weeks for manufacture or consult our sales engineers if a fast delivery is required. Our stock holding is constantly growing to meet customer demands.

Download Datasheet Download DTS Mounting GuideSPECIFICATION

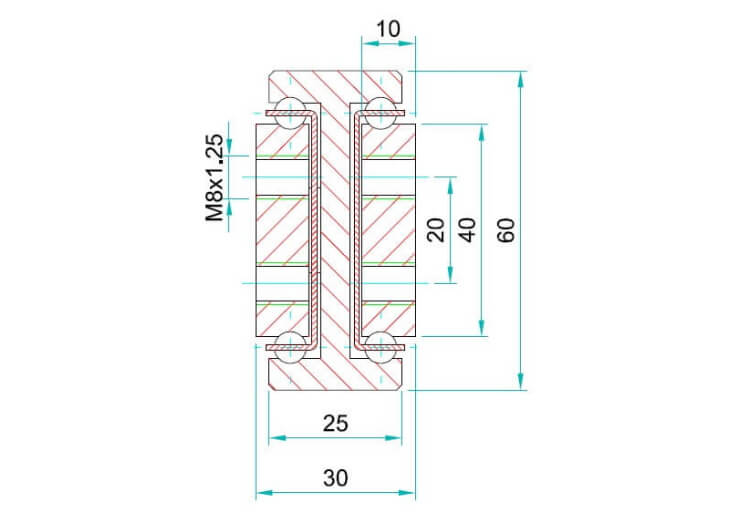

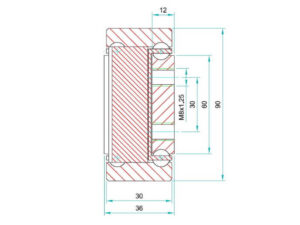

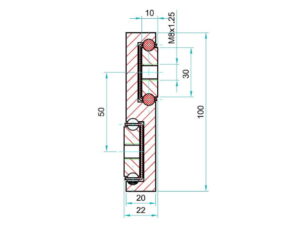

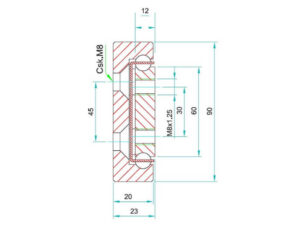

Space Envelope Width: 30mm

Height: 60mm

Closed Length: 250-2000mm

Extension Length: 250-2000mm

Maximum Load Capacity: 180-600 kg/pair

Extension Type: Total

Material: Steel

Paul Gerrard –

These are an almost exact replacement for slides we have been getting from a Uk agent. Unfortunately we were not advised of their extended factory shutdown, so we had to source other product at short notice.

The DTS60 slide compares favourably with a more precise extension. Further they were much reduced in price and received within a day.

Brian –

Thank you Colleen for the help over the last few weeks while we discussed various products. Having them all to compare within one site made it a lot easier, so we settled on the DTS60 and the first batch arrived last week.They are working well, the customer is pleased and I believe we have placed a scheduled order already.

Brian

Anonymous –

this is just an awesome slide. One handed operation on a 900Lb load. Super smooth operation. Im sure it can handle larger loading. Heavy duty end stops. Nice and compact

Easy guys to deal with. fast shipping from stock. Absolutely would recommend.

Ryan Ford –

Four slides length 60 inches delivered to Chicago in five days. Freight was negligible. These are due to be fitted on a rig, so pretty demanding load wise.

Same time tech advise too, which helped turn the project quickly. These guys are switched on.

Jason –

we had 2 pairs of the DTS60 delivered in two days at 1.6 metres from stock. Amazing service compared to the also rans. Quoted at 11pm and ordered 30 mins later.

Anonymous –

The slides have a smooth action under load. There are heavy duty stops fitted front and rear to contain the balls. The beams are zinc plated with passivation. They are very heavy, with the central beam able to support extreme loads. Delivery was quick and the tech support in line with other comments.

Geoff Travis –

I allowed three weeks for this to be delivered and they arrived next day. Four pieces at length 750mm. They look pretty awesome slides compared to the lighter weight ones we usually take.

Anonymous –

I was pleased to see the slides arrive five days after ordering in Ontario, Canada. I took the 600mm length and they look very meaty indeed. I think there is some serious safety margin in these sliders, which suits me fine. I will post further when we have carried out the testing, but I see no issue here.

Mark Webber. MWD –

I was surprised at receiving a call back from your sales office immediately after placing my inquiry thru this site. I work out of ours as a design engineer and getting product support New Year’s Eve, 8pm was totally unexpected. After reading other reviews, this appears to be a common rating. I was able to download 3D models and get price info instantly.

Peter Wilson –

thanks Jon for the late night technical advise to push this project forwards. We have won the contract and the slides came in well under budget. The DTS60 is a beast of a unit!

Anonymous –

The DTS60 is an extreme slide. Far heavier than sliders we have used before and certainly up to the job. There is another supplier in the UK who we have used previously for this slide, but problems with supply and inconsistent pricing forced us to look elsewhere and found this site, which is Sliding Systems online shop. The DTS slide has milled ball races which lead to a highly accurate travel, unlike the previous slide which was fitted very loosely.

Then there was the price, the other supplier wanted £140 a slide against the DTS60 at £89. They also had a very high shipping charge probably because it’s manufactured in France.

All in all this is a very professional company to deal with.

Andy Greaves –

After a morning of calling other slide manufacturers I found Sliding Systems. Promounts is their online sales site.

I got put through to John, who fortunately had a lot of experience in mounting extreme draws on trucks. He recomended the DTS60 due to the high level of shock they can take. (I was offered aluminum by other dealers in the US, which was not suitable for the 6′ draw width)

The slides were delivered in 3 weeks and they have fitted well. These slides are exceptionally heavy duty.