Sliding Systems Roll Out Freezer Slides For Global Restaurant Chain

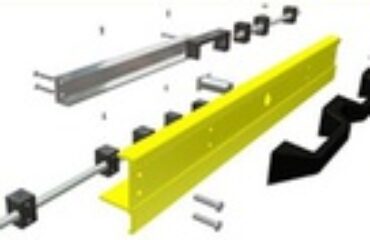

Sliding Systems’ design engineers are a versatile bunch, capable of drawing on many years of industrial drawer slide experience. So when a requirement was received for a next generation commercial freezer design, they jumped at the opportunity. The brief was to design a totally bespoke low profile slide in stainless steel with some special features which weren’t readily available from conventional manufacturers.

Chilled air is blown around catering freezers in order to maintain product quality, so when the drawers are opened to access product there is the risk of losing temperature control. Our designers came up with a novel solution to fit a snap back, piston style damper which allows the operator to let go and self close at speed. NSF compliance and bespoke drawer bracketry were also high on the wish list.

When you’re going to be supplying one of the world’s largest restaurant chains then the product has to be proven to be absolutely up to the job. A heavy duty piston was fitted on an unevenly loaded drawer, on one side only, to replicate in store service life. This puts a lot of stress on the pair and our industrial slide experience provided solutions to make the slides as sturdy as possible.

Jon Lye, Technical Director explains ” I was aware that the life test was going to be stringent in every way possible, as our standard within the industry is for the working slides to survive 100,000 cycles. Then I got a call from the manufacturer stating that the test had to stop at 525,000 cycles due to piston failure. This was new territory and the conclusion of many months of design work with a dedicated team on both sides”

“Our manufacturing partners have the capacity to deal with similarly large projects, with production capacity well in excess of 250,000 pairs of slides passing through dedicated production lines on a monthly basis. Design is just a single step in the supply chain and we had to be sure that the tooling investment supported total mechanised production, which guarantees a high quality product, regardless of volume. You simply cannot hand fit ball bearings on this scale”

The 3522 OAT slides are now in volume production and being fitted by the manufacturer to freezers for global despatch.